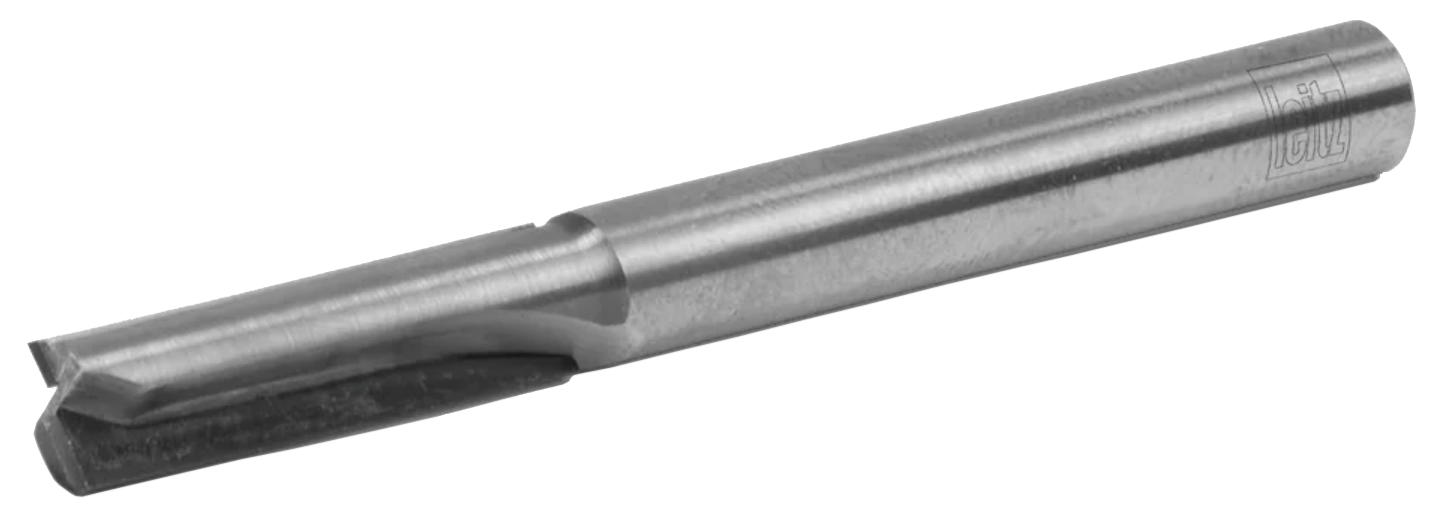

FixChip®

One-Step Production. Maximum Efficiency.

Revolutionize production with FixChip!

In one, single production run, all milling and joint processing are done. No extra machines and no manual finishing needed.

The result?

Faster, more efficient production cycles, much higher precision, and significantly lower investment in machinery.

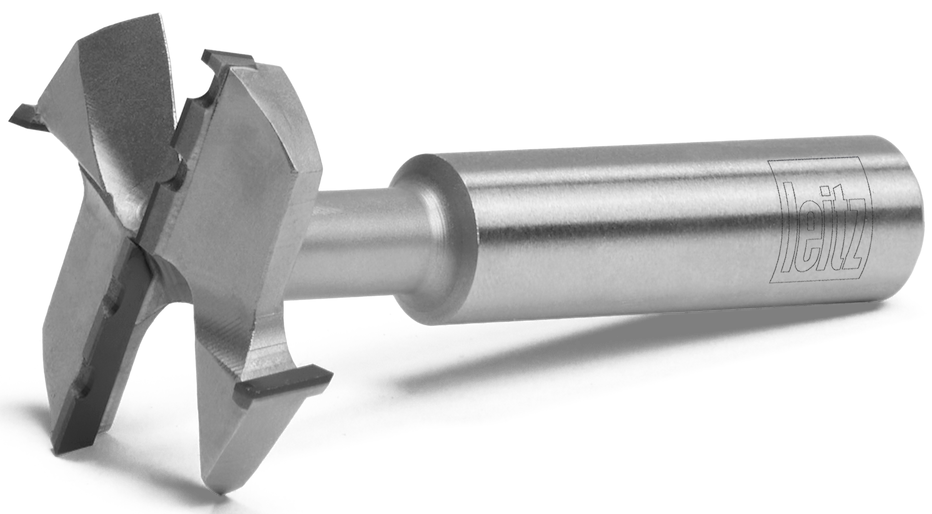

100% Accuracy

Every connection is CNC-machined with the main spindle for flawless precision.

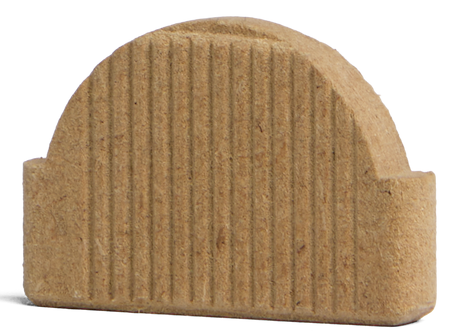

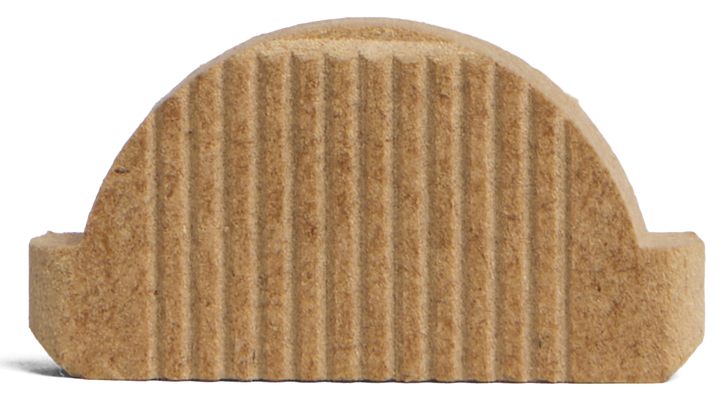

Strong Tight Joints

The FixChip shape is engineered for superior fit and durability.

Eco-Friendly

Made from high-density fiberboard, FixChips are fully sustainable.

One-Step Production. Maximum Efficiency.

Revolutionize production with FixChip!

In one, single production run, all milling and joint processing are done. No extra machines and no manual finishing needed.

The result?

Faster, more efficient production cycles, much higher precision, and significantly lower investment in machinery.

100% Accuracy

Every connection is CNC-machined with the main spindle for flawless precision.

Strong Tight Joints

The FixChip shape is engineered for superior fit and durability.

Eco-Friendly

Made from high-density fiberboard, FixChips are fully sustainable.

One-Step Production. Maximum Efficiency.

Revolutionize production with FixChip!

In one, single production run, all milling and joint processing are done. No extra machines and no manual finishing needed.

The result?

Faster, more efficient production cycles, much higher precision, and significantly lower investment in machinery.

100% Accuracy

Every connection is CNC-machined with the main spindle for flawless precision.

Strong Tight Joints

The FixChip shape is engineered for superior fit and durability.

Eco-Friendly

Made from high-density fiberboard, FixChips are fully sustainable.

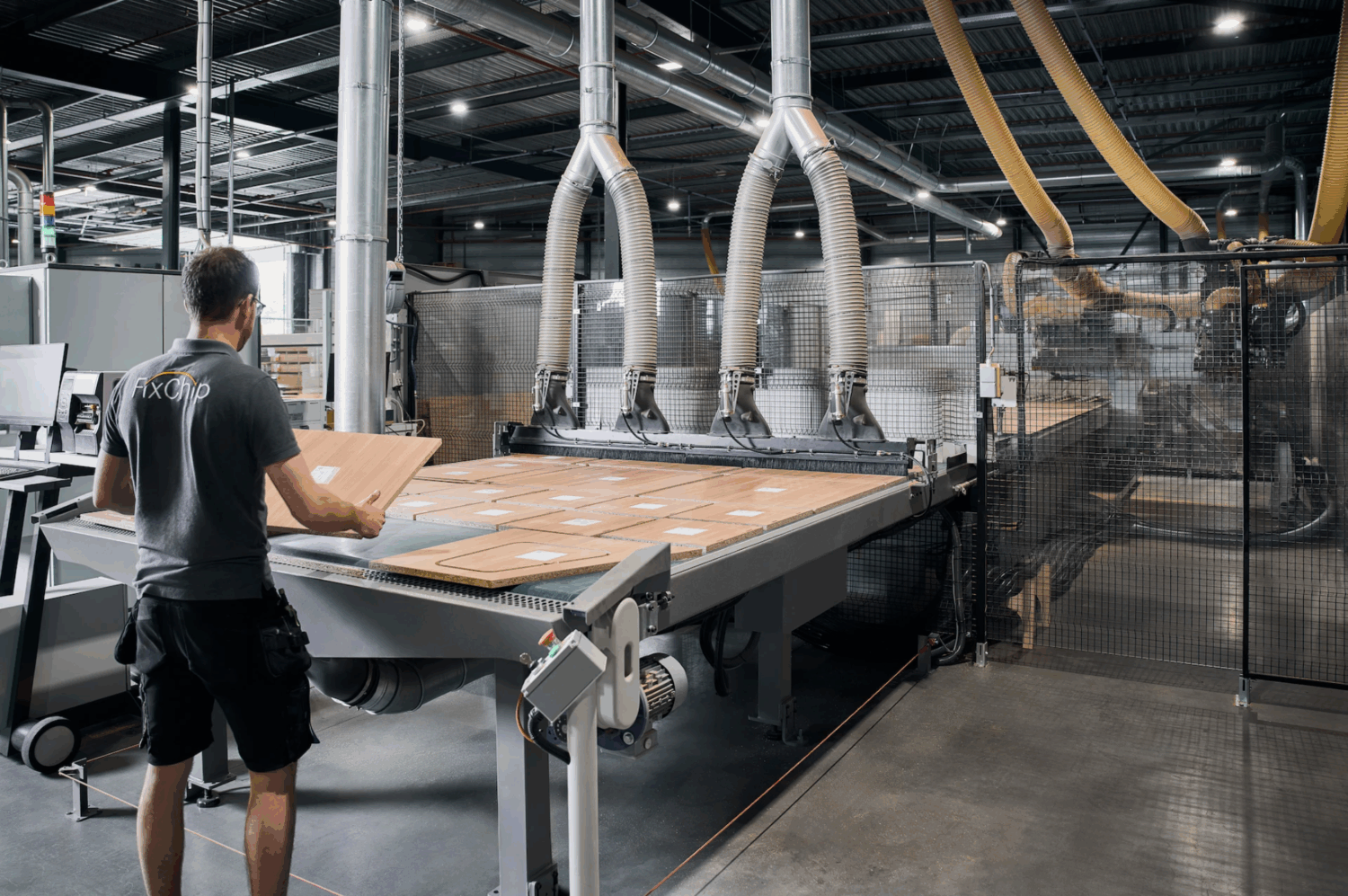

See FixChip In Action

FixChip can be used on all nesting machines and with any software. Combined with a nesting machine and CAD/CAM software, it optimizes the entire process from production to assembly.

Our Trusted Partners

Contact Us

Interested in our FixChip?

Whether you’d like a quote, have a question,

or just want to learn more – we are ready to help.

Contact Us

Interested in our FixChip?

Whether you’d like a quote, have a question,

or just want to learn more – we are ready to help.